Labor posted against a work order and operation can result in material movement based on the Order Policy and Move Scheme configuration. For example, a work order has three operations – 10, 20, and 30. A user posts a Quantity Complete on operation 10 and this quantity is deducted from the Quantity Available of operation 10 and added to the Quantity Available for operation 20.

WIP allows users to post the following quantities against a work order:

Quantity Completed for the current operation

Quantity Scrapped for the current operation

Quantity Rejected for the current operation

The Action Move Quantity form is used to track quantity movement between operations resulting from an event posting. You can also track quantity changes on the Quantity tab of the Order form.

See Also:

Skip Quantity on Non Count Point Operations

This feature requires the following:

You must have the WIP module included in your license file.

The WIP module must be enabled.

To check if the module is included in your license and enabled:

Click Main Menu > Configuration > System > Licensing.

On the License Modules tab, select the Module Name called WIP.

The following boxes must be checked: Licensed and Module Enabled.

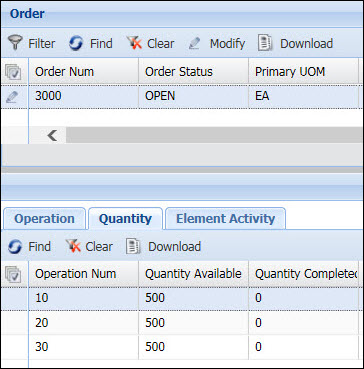

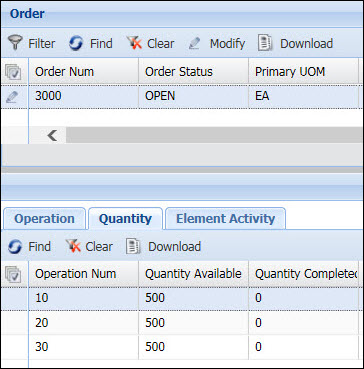

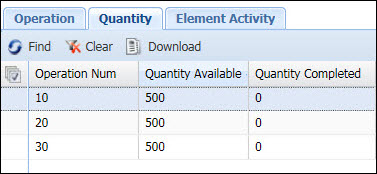

Work Order 3000 has Operations 10, 20, and 30. Each operation has a Quantity Available of 500 and a Quantity Complete of zero. The STANDARD Move Scheme is used (all move transactions are allowed).

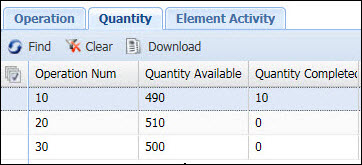

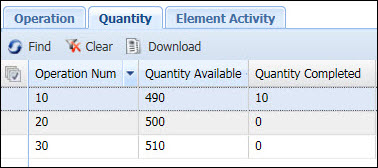

A person reports a Quantity Complete of 10 on Work Order 3000, Operation 10. The Quantity Available for Operation 10 is reduced from 500 to 490. The Quantity Complete moves to the next operation (Operation 20) and its Quantity Available increases from 500 to 510.

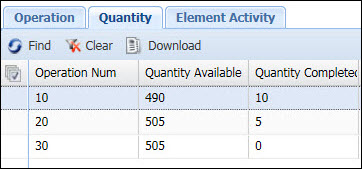

Later, the person reports a Quantity Complete of 5 on Work Order 3000, Operation 20. The Quantity Available for Operation 20 is reduced from 510 to 505. The Quantity Complete moves to the next operation (Operation 30) and its Quantity Available increases from 500 to 505.

A count point is an operation that is a milestone or pay point. Typically, only count point operations will receive quantity when quantity is completed on a previous operation. When quantity moves to the next operation, if that operation is not a count point it will be skipped, and the quantity will move to the next count point operation instead.

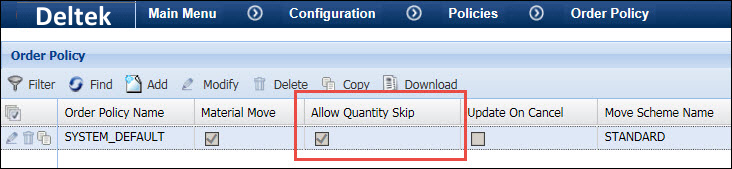

To configure this feature, you must check the Allow Quantity Skip box in your Order Policy.

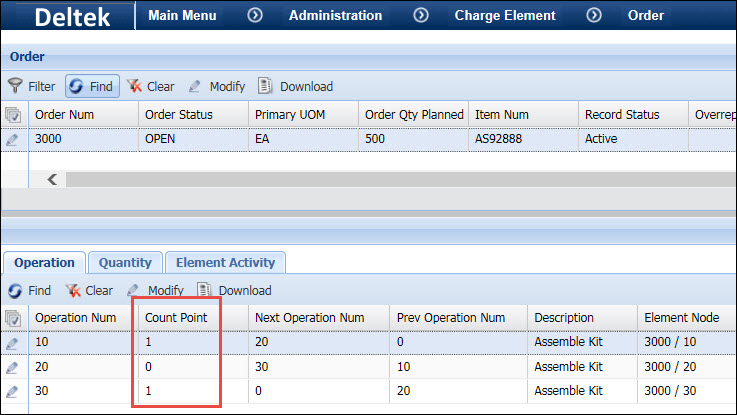

You must also make sure the correct operations are designated as count points; these settings can be modified on the Operation tab of the Order form.

In the example below, Operations 10 and 30 are count points but Operation 20 is not a count point. Allow Quantity Skip is checked in the Order Policy.

A Quantity Complete of 10 is reported on Operation 10. The completed quantity moves from the Quantity Available of Operation 10 to the Quantity Available of Operation 30 (the next count point). Because Operation 20 is not a count point, it was skipped.

Event Configuration

You need to configure your work order events for material movement. The System Required TEMPLATE_WORKORDER event includes the event prompts and validations necessary for material movement. You can copy this event and modify the duplicate if needed.

Move Scheme

You need to define a Move Scheme that indicates the type of move transactions that are allowed by your company. The STANDARD Move Scheme allows all move transactions. You will need to select a Move Scheme in your Order Policy.

Order Policy

You will need to check Material Move in your Order Policy. You also need to select a Move Scheme for your Order Policy. If you are using count point operations, make sure you also check Allow Quantity Skip.

Order form / Operation tab

You can use the Operation tab of the Order form to enable or disable the Count Point setting for an operation.